Jet fans

History

Since the early 1960's jet fans have been used to ventilate road tunnels with longitudinal ventilation. One of the earliest theoretical background papers was presented by a member of the Witt-Group of companies:

U. Meidinger: Längslüftung von Autotunneln mit Strahlgebläsen, Switzerland. Building Journal, 82. Year, Issue 28, 09. July 1964:

Since then we have equipped a large number of tunnels worldwide with jet and exhaust fans. The reference list only includes the current design of fans which was used in tunnels since 1987.

Product Description

Witt & Sohn, known as one of the leading fan manufacturers, has become one of the leading brand names for tunnel- and metro-ventilation systems during the last 20 years. This was achieved by continuous development of:

- jet fans

- large axial flow fans for fresh air supply and exhaust mode.

The jet fans are available as an

- asymmetric type, developed with high efficiency for one direction

- symmetric type, with a partially reversibility (40%; 60%; 90%) in both directions.

With the standard jet fans thrust from 35 N up to 3500 N is available. Higher values are possible on request. With different length for the silencers, nearly every required sound pressure level can be reached. With the special developed impellers (cast in steel-bolts, etc.) very high tip speeds and very high temperatures are possible. X-raying of the impeller blades and the impeller hub is not necessary, but can be done on customer request.

The latest generation of jet fans from Witt & Sohn is already robbing the ERP EU-Ecodesign 2020 fronts today. The efficiency limit of these new jet fans, at approx. 70%, is significantly higher than the usual market efficiency levels.

The jet fans are tested according to ISO 13 350, the axial fans according to ISO 5801. Additionally all fans have to pass the factory routine test before delivery. The jet and axial fans are tested and certified according to EN 12 101−3.

- Size: 400 to 1800 mm (bigger sizes on request)

- Casing thickness: 4 − 10 mm

- Impeller types: P, N, M, NR, MR (adjustable pitch at impeller standstill)

Design

- with inlet cone (for one direction: type GD / for both directions: type GDR)

- with inlet cone and silencer (for one direction: type GT / for both directions: type GR)

Material

Impeller:

- corrosion resistant cast aluminium or

- steel impeller

Casing:

- steel (S235JRG2, according to EN 10 025) or

- stainless steel (1.4571 = X6CrNiMoTi17−12−2, 1.4301 = X4CrNi18−10, according to EN 10 088−2)

Silencer:

- steel (S235JRG2 / perforated sheet: stainless steel 1.4571, 1.4301) or

- stainless steel (1.4571, 1.4301)

Mounting structure (will be adapted to the respective tunnel profile):

- steel (S235JRG2) or

- stainless steel (1.4571,1.4301,(1.4529))

Surface treatment:

- Painting (e.g. 2 component epoxy paint)

- Hot dip galvanizing + painting (e.g. 2 component epoxy paint)

- Weldings passivated (stainless steel)

Temperature resistance

- According to customer request (e.g. 250°C / 90 min.; 200°C / 2h, etc.)

- F200 according to EN 12 101-3, Certification by the MPA Braunschweig

- F300 according to EN 12 101-3, Certification by the MPA Braunschweig

- F400 according to EN 12 101-3, Certification by the MPA Braunschweig

- In our own heat test chamber we are able to do all kind of heat tests according to customer wishes, certified by GL, TÜV, etc.)

Standard Accessories

- Banana Jet®−design (about 30 % higher volume flow in the tunnel with the same power consumption!)

- Vibration attenuators

- Protection grills

- Safety wires (material: 1.4401)

- Dowels (1.4571 / 1.4529)

- Tear off guard

- Vibration control

- Guide vanes

Motors

- Motor frame sizes: 63 to 315

- Protection class: IP55 (on request IP65)

- Bearings: life-time-lubrication (on request with relubrication device)

- Insulation class: F, H or special

- Temperature resistant motors are tested according to EN 12 101-3

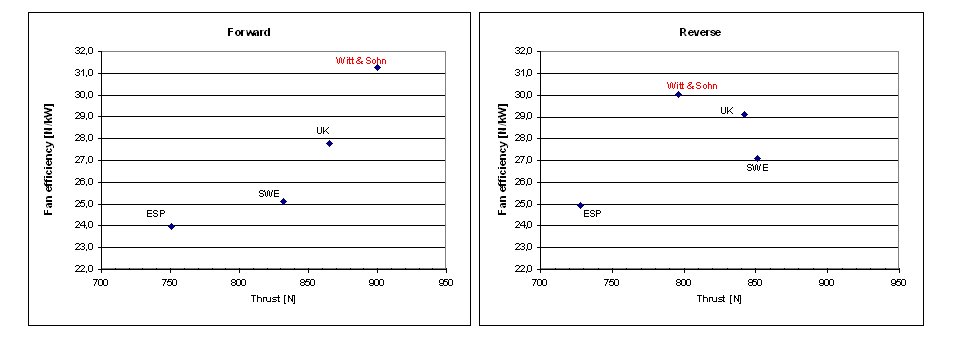

Market comparision table

Some months ago in a certified laboratory jet fans of several European fan manufacturers have been tested. The jet fans were

- reversible ones,

- with silencers ( L= 1 x D ),

- impeller size 1000mm,

- heat resistance class F400 acc. to EN12101-3.

After having normalised the impeller gap the results have been compared. As shown in the curves below the Witt & Sohn jetfan was the most efficient one of all of them.